Nyob rau hauv xyoo tas los no, nrog kev txhim kho txuas ntxiv ntawm thev naus laus zis, laser welding ntawm cov yas yuav maj mam qhia qhov kev loj hlob yav tom ntej.Nyob rau hauv ob peb xyoos dhau los, qee cov thev naus laus zis laser tsis tau tawg, thiab tus nqi laser kuj tseem siab.Piv nrog rau kev sib tsoo ib txwm siv, kev nqis peev ib zaug yog qhov loj, uas yuav tsis tsim cov txiaj ntsig sai.Tab sis tam sim no lub economic kom zoo dua ntawm laser yog highlighted.Lub laser vuam ntawm cov yas tuaj yeem txo qhov nyuaj rau cov neeg tsim qauv tsim cov khoom.

Tam sim no, ntau yam khoom (xws li tsheb semiconductor kev lag luam, tshuaj thiab khoom noj khoom haus kev lag luam, thiab lwm yam) muaj cov kev cai siab heev rau kev ua kom raug thiab zoo nkauj tsos, uas ua rau laser vuam ua ib tug tsim nyog txheej txheem rau zus tau tej cov khoom no thiab txhawb txoj kev loj hlob ntxiv. laser vuam technology.

Qhov ze dua qhov sib xws, fusion kub thiab sib txuam ntawm cov yas laser vuam yog, qhov zoo dua nws cov nyhuv yuav.Daim ntawv thov hom ntawm cov yas laser vuam yog txawv ntawm cov hlau vuam, nrog rau kev sib txuas ib puag ncig vuam, quasi synchronous vuam, synchronous vuam thiab irradiation daim npog qhov ncauj welding.Olay Optoelectronics yuav qhia luv luv txog cov qauv vuam no.

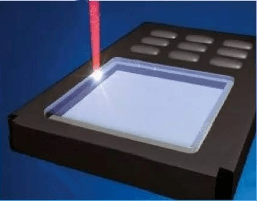

1. Profile vuam

Lub laser txav raws cov kab contour ntawm cov yas welding txheej thiab melts nws maj mam muab cov yas txheej ua ke;Los yog txav cov qhaub cij raws li lub teeb laser ruaj khov kom ua tiav lub hom phiaj ntawm vuam.

Hauv kev siv cov tswv yim, contour welding muaj cov kev xav tau siab rau qhov zoo ntawm kev txhaj tshuaj molded qhov chaw, tshwj xeeb tshaj yog rau daim ntawv thov ntawm cov kab sib txuas xws li roj-gas separators.Nyob rau hauv cov txheej txheem ntawm cov yas laser vuam, contour welding tuaj yeem ua tiav qee qhov kev nkag mus ntawm cov vuam kab, tab sis qhov kev nkag mus yog me me thiab tsis tuaj yeem tswj tau, uas yuav tsum muaj qhov deformation ntawm kev txhaj tshuaj molding qhov chaw yuav tsum tsis txhob loj dhau.

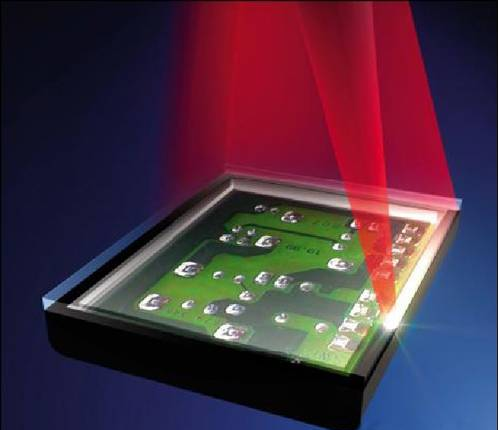

2. Synchronous vuam

Lub laser beam los ntawm ntau lub diode lasers yog zoo li tus los ntawm optical ntsiab.Lub laser beam yog coj raws txoj kab contour ntawm vuam txheej thiab ua kom sov ntawm qhov vuam seam, kom tag nrho cov kab contour yog yaj thiab sib koom ua ke tib lub sijhawm.

Synchronous vuam yog tsuas yog siv nyob rau hauv tsheb teeb thiab kev kho mob kev lag luam.Synchronous welding yog ib tug ntau beam, kho qhov muag shaping qhia lub teeb qhov chaw ntawm vuam khiav, uas yog yus muaj los ntawm kev txo nyob rau hauv kev nyuaj siab.Vim hais tias cov kev xav tau kuj yog siab heev thiab tus nqi tag nrho yog qhov siab, nws yog dav siv hauv kev kho mob.

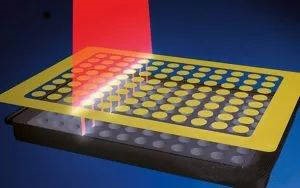

3. Scanning vuam

Scanning welding tseem hu ua quasi synchronous welding.Kev siv thev naus laus zis thev naus laus zis sib xyaw ua ke saum toj no ob lub vuam thev naus laus zis, uas yog, ntu ntu ntu vuam thiab synchronous vuam.Lub reflector yog siv los ua kom muaj kev kub ceev laser beam nrog qhov ceev ntawm 10 m / s, uas txav raws qhov yuav tsum tau welded, ua rau tag nrho cov vuam ib ntus maj mam kub thiab fuse ua ke.

Quasi synchronous vuam yog feem ntau siv.Hauv kev lag luam tsheb, nws siv XY high-frequency galvanometer sab hauv.Nws lub hauv paus yog los tswj cov yas vuam vau ntawm ob cov ntaub ntawv.Contour welding yuav ua rau muaj kev ntxhov siab loj, uas yuav cuam tshuam rau kev sib khi ntawm cov khoom.Quasi synchronization yog hom scanning ceev, thiab nrog kev tswj tam sim no, nws tuaj yeem tshem tawm kev ntxhov siab sab hauv.

4. Rolling vuam

Rolling welding yog ib qho tshiab ntawm laser yas vuam txheej txheem, uas muaj ntau yam sib txawv.Muaj ob lub ntsiab ntawm rolling welding:

Thawj yog Globo pob welding.Muaj ib lub tshuab cua cushion iav pob qhov kawg ntawm lub laser lens, uas tuaj yeem tsom lub laser thiab clamp cov khoom yas.Nyob rau hauv cov txheej txheem vuam, Globo lens yog tsav los ntawm lub suab platform los ua kom tiav cov vuam los ntawm dov raws txoj kab vuam.Cov txheej txheem tag nrho yog yooj yim li kev sau ntawv nrog tus cwj mem ballpoint.Globo welding txheej txheem tsis tas yuav tsum muaj kev sib tw sab sauv, thiab tsuas yog xav tau los tsim cov khoom lag luam hauv qab pwm.Globo pob welding txheej txheem kuj muaj cov txheej txheem sib txawv ntawm cov menyuam vuam txheej txheem.Qhov txawv yog tias lub iav pob qhov kawg ntawm lub lens hloov mus rau hauv lub cylindrical iav chim kom tau txais ib qho dav laser ntu.Cov menyuam welding yog tsim rau dav vuam.

Qhov thib ob yog TwinWeld vuam txheej txheem.Cov txheej txheem yas laser welding no ntxiv cov hlau rau qhov kawg ntawm lub lens.Thaum lub sij hawm vuam txheej txheem, cov menyuam nias lub npoo ntawm cov vuam kab rau vuam.Qhov kom zoo dua ntawm cov txheej txheem yas laser vuam no yog cov hlau nias lub log yuav tsis hnav, uas yog qhov tsim nyog rau kev tsim khoom loj.Txawm li cas los xij, lub siab ntawm cov menyuam lub siab ua haujlwm ntawm ntug ntawm txoj kab vuam, uas yog ib qho yooj yim los tsim torque thiab tsim ntau yam vuam tsis xws luag.Nyob rau tib lub sijhawm, vim tias lub lens qauv yog qhov nyuaj, nws nyuaj rau kev ua haujlwm vuam.

4. Rolling vuam

Rolling welding yog ib qho tshiab ntawm laser yas vuam txheej txheem, uas muaj ntau yam sib txawv.Muaj ob lub ntsiab ntawm rolling welding:

Thawj yog Globo pob welding.Muaj ib lub tshuab cua cushion iav pob qhov kawg ntawm lub laser lens, uas tuaj yeem tsom lub laser thiab clamp cov khoom yas.Nyob rau hauv cov txheej txheem vuam, Globo lens yog tsav los ntawm lub suab platform los ua kom tiav cov vuam los ntawm dov raws txoj kab vuam.Cov txheej txheem tag nrho yog yooj yim li kev sau ntawv nrog tus cwj mem ballpoint.Globo welding txheej txheem tsis tas yuav tsum muaj kev sib tw sab sauv, thiab tsuas yog xav tau los tsim cov khoom lag luam hauv qab pwm.Globo pob welding txheej txheem kuj muaj cov txheej txheem sib txawv ntawm cov menyuam vuam txheej txheem.Qhov txawv yog tias lub iav pob qhov kawg ntawm lub lens hloov mus rau hauv lub cylindrical iav chim kom tau txais ib qho dav laser ntu.Cov menyuam welding yog tsim rau dav vuam.

Qhov thib ob yog TwinWeld vuam txheej txheem.Cov txheej txheem yas laser welding no ntxiv cov hlau rau qhov kawg ntawm lub lens.Thaum lub sij hawm vuam txheej txheem, cov menyuam nias lub npoo ntawm cov vuam kab rau vuam.Qhov kom zoo dua ntawm cov txheej txheem yas laser vuam no yog cov hlau nias lub log yuav tsis hnav, uas yog qhov tsim nyog rau kev tsim khoom loj.Txawm li cas los xij, lub siab ntawm cov menyuam lub siab ua haujlwm ntawm ntug ntawm txoj kab vuam, uas yog ib qho yooj yim los tsim torque thiab tsim ntau yam vuam tsis xws luag.Nyob rau tib lub sijhawm, vim tias lub lens qauv yog qhov nyuaj, nws nyuaj rau kev ua haujlwm vuam.

Post lub sij hawm: Sep-23-2022