Cov khoom tshwj xeeb

Ib qho ntawm Cov Kub Kub Kub Tshaj Plaws rau Optical Fiber Laser Teeb Qhov Chaw

Nws tuaj yeem yog peb lub luag haujlwm kom txaus siab rau koj qhov kev nyiam thiab muaj peev xwm muab rau koj.Koj qhov kev txaus siab yog peb qhov khoom plig loj tshaj plaws.Peb tab tom nrhiav ua ntej ntawm koj qhov kev mus ntsib rau kev sib koom ua ke rau kev loj hlob rau Ib Qhov Kub Kub Tshaj Plaws rau Optical Fiber Laser Light Source, Hauv kev yuav los nthuav peb cov lag luam thoob ntiaj teb, peb feem ntau yog los ntawm peb cov neeg yuav khoom txawv teb chaws Sab saum toj zoo cov khoom lag luam thiab cov chaw muag khoom.

Nws tuaj yeem yog peb lub luag haujlwm kom txaus siab rau koj qhov kev nyiam thiab muaj peev xwm muab rau koj.Koj qhov kev txaus siab yog peb qhov khoom plig loj tshaj plaws.Peb tab tom nrhiav ua ntej ntawm koj mus ntsib rau kev sib koom ua ke kev loj hlob rauTuam Tshoj Optical Light Source thiab Fiber Ntau Qhov Chaw, Lub sijhawm luv luv, peb ua haujlwm rau peb cov neeg siv khoom ncaj ncees raws li Kev Ua Haujlwm Zoo Ua Ntej, Kev Ncaj Ncees Prime, Kev Xa Khoom Sijhawm, uas tau txais peb lub koob npe nrov thiab kev pabcuam zoo rau cov neeg siv khoom.Nrhiav rau pem hauv ntej ua haujlwm nrog koj tam sim no!

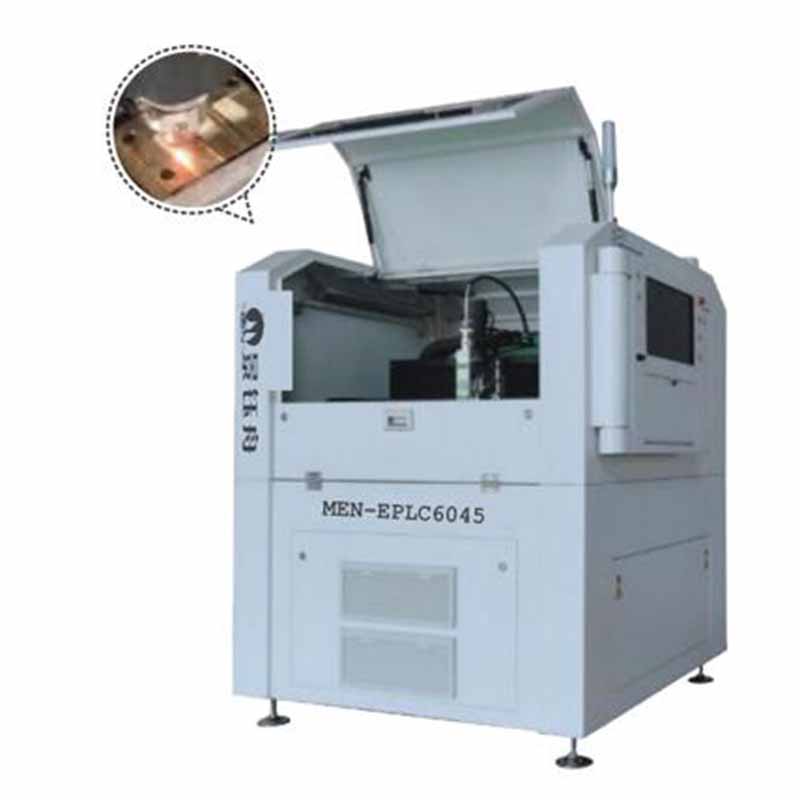

Technical Parameters

| 1 Kev ua haujlwm siab tshaj plaws | 1000mm / s (X) ; 1000mm / s (Y1 & Y2) 50mm / s (Z); |

| 1 Positioning raug | ± 3um (X) ± 3um (Y1 & Y2) ; ± 5um (Z) ; |

| Repetical positioning raug | ± 1um (X) ± 1um (Y1 & Y2) ± 3um (Z) ; |

| 1 Machining khoom | Al & Cu & W & Mo & Ni & Ti & Zn & Mg & Magnet & Silicon Steel & Hmoov Metallurgy, thiab lwm yam. |

| Khoom phab ntsa thickness | 0 ~ 2.0 ± 0.02 hli; |

| 1 Plane machining ntau | 450mm * 600mm; |

| Laser hom | Fiber laser npav |

| 1 Laser wavelength | 1030 ~ 1070 ± 10nm; |

| 1 Laser zog | CW1000W&QCW150W& QCW300W & QCW450W rau kev xaiv; |

| 1 Fais fab mov | 220V ± 10%, 50Hz; AC 20A (main Circuit Court breaker) ; |

| 1 Cov ntaub ntawv hom | DXF, DWG; |

| Qhov ntev | 1280mm * 1320mm * 1600mm; |

| 1 Cov khoom hnyav | 1500Kg; |

Qauv Exhibition

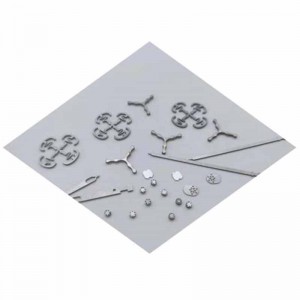

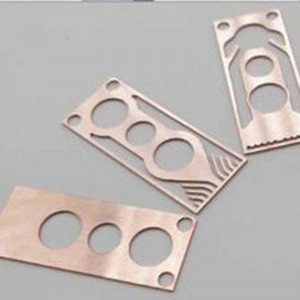

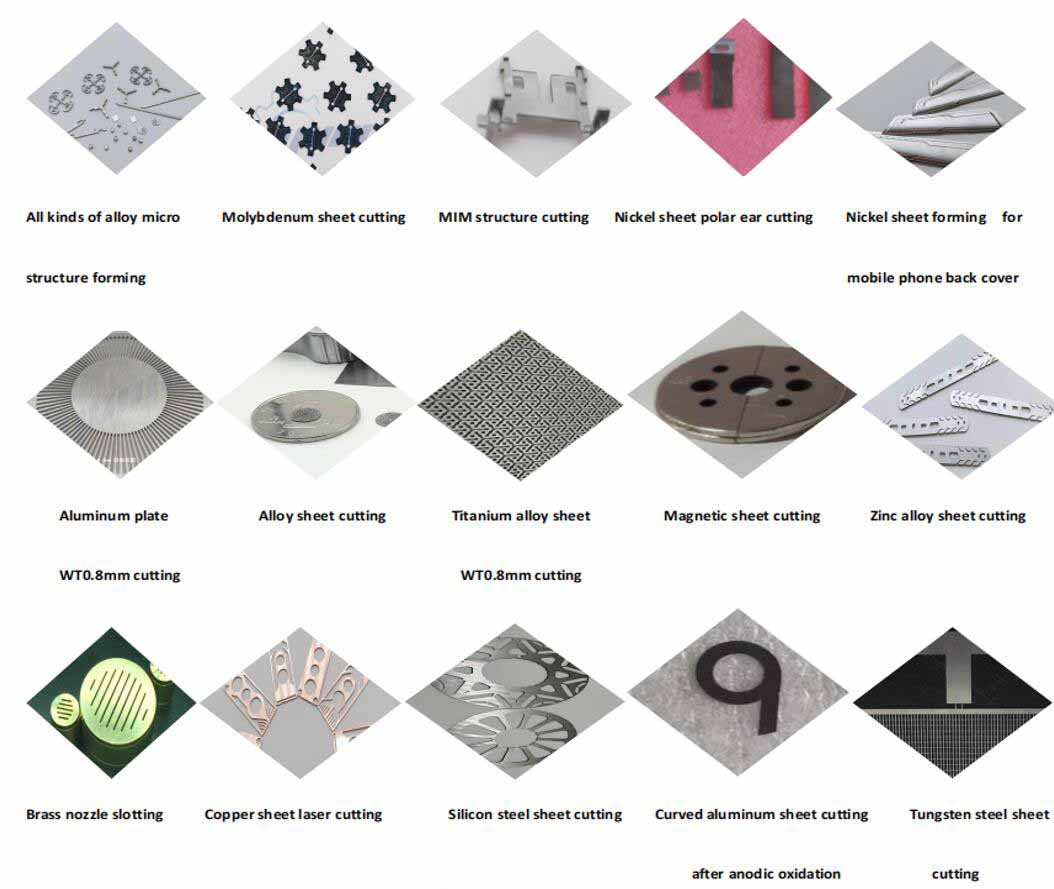

Daim ntawv thov Scope

Laser micro-machining ntawm planar thiab nkhaus nto ntawm Al & Cu & W & Mo & Ni & Ti & Zn & Mg & Magnet & Silicon Steel & Hmoov Metallurgy, thiab lwm yam.

High precision machining

1.Me txiav seam dav: 15 ~ 35um

2.High machining raug ≤ 10um

3.Zoo zoo ntawm incision: du incision & me me tshav kub cuam tshuam cheeb tsam & tsawg burr

4.Size refinement: yam tsawg kawg nkaus cov khoom loj 50um

Muaj zog adaptability

1.With zoo machining thev naus laus zis muaj peev xwm ntawm laser txiav, drilling thiab slotting rau planar thiab nkhaus nto seev

2.Can txheej txheem Al & Cu & W & Mo & Ni & Ti & Zn & Mg & Magnet & Silicon Steel & Powder Metallurgy thiab lwm yam ntaub ntawv

3.Equipped nrog tus kheej-tsim tsav ncaj qha mobile ob chav tsav precision txav platform, granite platform, aluminium alloy thiab granite beam rau xaiv

4.Muab qhov kev xaiv ua haujlwm ntawm ob qhov chaw nres tsheb & Kev Pom Kev Pom Zoo & tsis siv neeg pub noj thiab tshem tawm qhov system & dynamic xyuas ntawm machining

5.Equipped nrog tus kheej-tsim ntev / luv focal ntev ntse nozzle & tiaj nozzle zoo laser txiav taub hau

6.Equipped nrog cov khoom siv modular txais thiab desusting piping system

7.Muab nws tus kheej tsim txav nro ncej & ruaj nro ncej & nqus adsorption & honeycomb phaj thiab lwm yam.

8.Equipped nrog tus kheej-tsim 2D & 2.5D & 3D CAM software system rau laser micro-machining

Yooj yim tsim

1. Ua raws li lub tswv yim tsim ntawm ergonomics, nws yog exquisite thiab concise

2.Qhov kev sib xyaw ua ke ntawm software thiab kho vajtse ua haujlwm yog hloov tau, txhawb kev ua haujlwm ntawm tus kheej thiab kev tswj hwm kev tsim khoom ntse

3.Txhawb qhov zoo & tsim tshiab los ntawm qib tivthaiv mus rau qib system

4.Open hom tswj, laser micro-machining software system, yooj yim rau kev khiav lag luam & intuitive interface

Daim ntawv pov thawj technical

CE

ISO9001

TIAB SA 16949

fiber laser qhov chaw manufacturers

Cov xov xwm ntsig txog

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur