Cov khoom tshwj xeeb

Nrov Tsim kom zoo dua OEM dabtsi yog khoov Sheet Hlau Laser Txiav Part Hoobkas Nqe

Ua lub luag haujlwm tag nrho kom txaus siab rau txhua qhov kev xav tau ntawm peb cov neeg yuav khoom;tau txais kev nce qib txuas ntxiv los ntawm kev txhawb nqa kev nce qib ntawm peb cov neeg siv khoom;loj hlob los ua qhov kawg kev koom tes ruaj khov ntawm cov neeg siv khoom thiab ua kom muaj kev txaus siab ntawm cov neeg yuav khoom rau Kev Tsim Nrov Zoo rau OEM Bending Sheet Hlau Laser Txiav Part Hoobkas Nqe, Ib txwm rau feem coob ntawm cov neeg siv khoom lag luam thiab cov neeg lag luam muab cov khoom zoo tshaj plaws thiab cov kev pabcuam zoo tshaj plaws.Zoo siab txais tos tuaj koom nrog peb, cia kev tsim kho tshiab ua ke, ua npau suav ya.

Ua lub luag haujlwm tag nrho kom txaus siab rau txhua qhov kev xav tau ntawm peb cov neeg yuav khoom;tau txais kev nce qib txuas ntxiv los ntawm kev txhawb nqa kev nce qib ntawm peb cov neeg siv khoom;loj hlob los ua qhov kawg kev koom tes ruaj khov ntawm cov neeg siv khoom thiab ua kom muaj txiaj ntsig zoo ntawm cov neeg yuav khoom rauTuam Tshoj Hlau Casting Part thiab Hlau Txiav Part, Peb tenet yog "kev ncaj ncees ua ntej, zoo tshaj plaws".Tam sim no peb muaj kev ntseeg siab los muab kev pabcuam zoo thiab cov khoom zoo rau koj.Peb cia siab tias peb tuaj yeem tsim kom muaj kev sib koom tes ua lag luam nrog koj yav tom ntej!

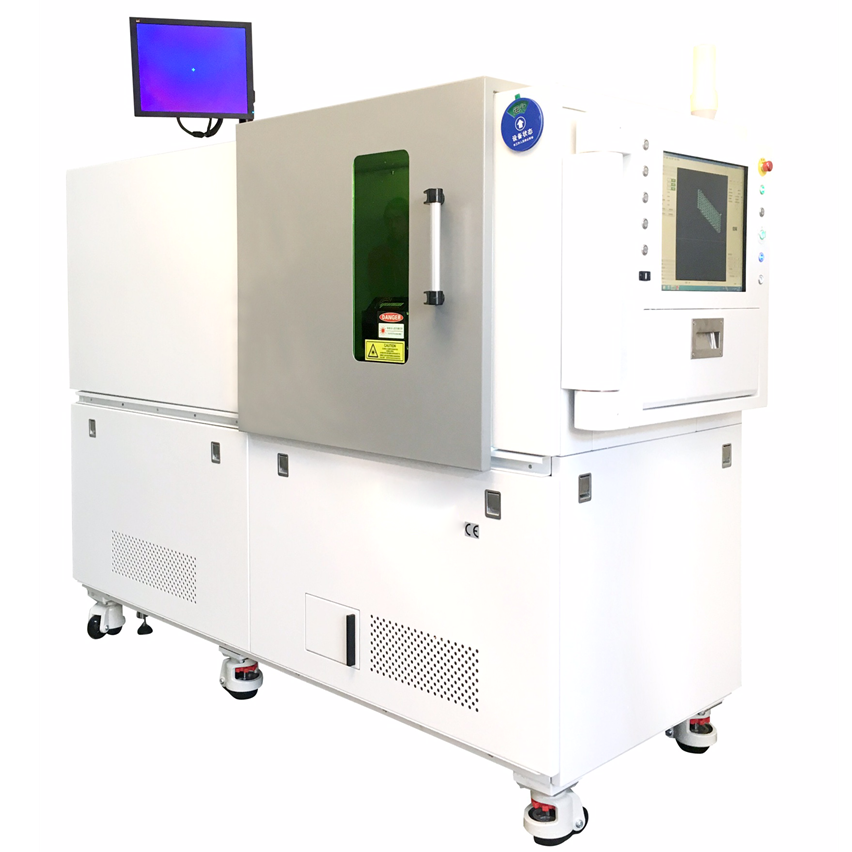

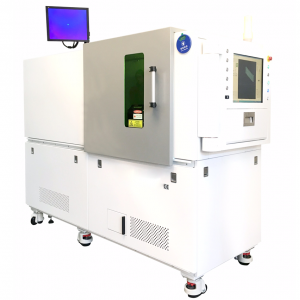

YC-SLC300

TechnicalParameters:

| Kev khiav hauj lwm ceev tshaj plaws | 300mm / s (X) ; 100mm / s (Y) rau kev xaiv ; 100mm / s (Z) ; 600rpm (θ) |

| Positioning raug | ± 1um (X) ± 3um (Y) rau kev xaiv; ± 3um (Z) ; ± 15arcsec (θ) ; |

| Repetical positioning raug | ± 0.2um (X) ± 1um (Y) rau kev xaiv; ± 1um (Z) ; ± 3arcsec (θ) |

| Txiav seam dav | 15-25 hnub |

| Kev sib haum xeeb ntawm qhov dav dav | <± 5um; |

| Machining khoom | 316L & Ni-Ti & L605 & Fe & Mg & Zn thiab lwm yam ntaub ntawv alloy |

| Tube qhov ntev | <2.5m (kev txhawb nqa kev txhawb nqa) |

| Ua phab ntsa thickness | 0 ~ 0.3 ± 0.02 hli; |

| Ua yeeb nkab txoj kab uas hla | Φ0.1 ~ Φ7.5 ± 0.02 hli; |

| Ib leeg ua ntau yam | 0 ~ 300mm (ntev cov khoom yuav raug machined los ntawm segmented splicingmethod); |

| Laser hom | Fiber ntau laser; |

| Laser wavelength | 1030-1070 ± 10nm; |

| laser zog | 100W & 200W & 300W rau kev xaiv; |

| Cov khoom siv hluav taws xob | 220V ± 10%, 50Hz; AC 20A (lub ntsiab Circuit Court breaker); |

| Cov ntaub ntawv hom | DXF, DWG; |

| Cov khoom siv qhov ntev | 2000mmx1000mmx1600mm; |

| Khoom hnyav | 1500Kg; |

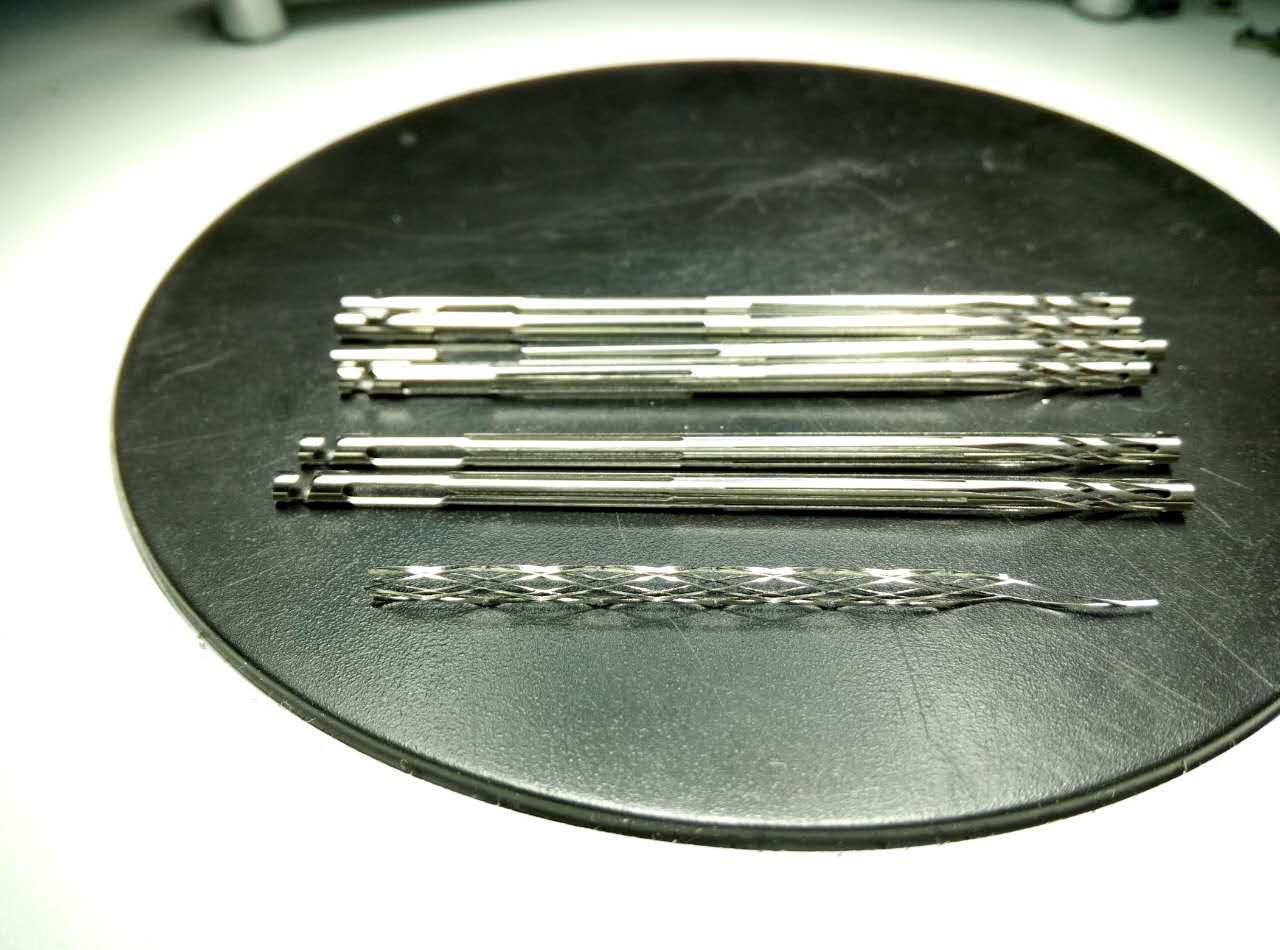

Qauv Exhibition:

316L & L605 liab

hlau coronary stent

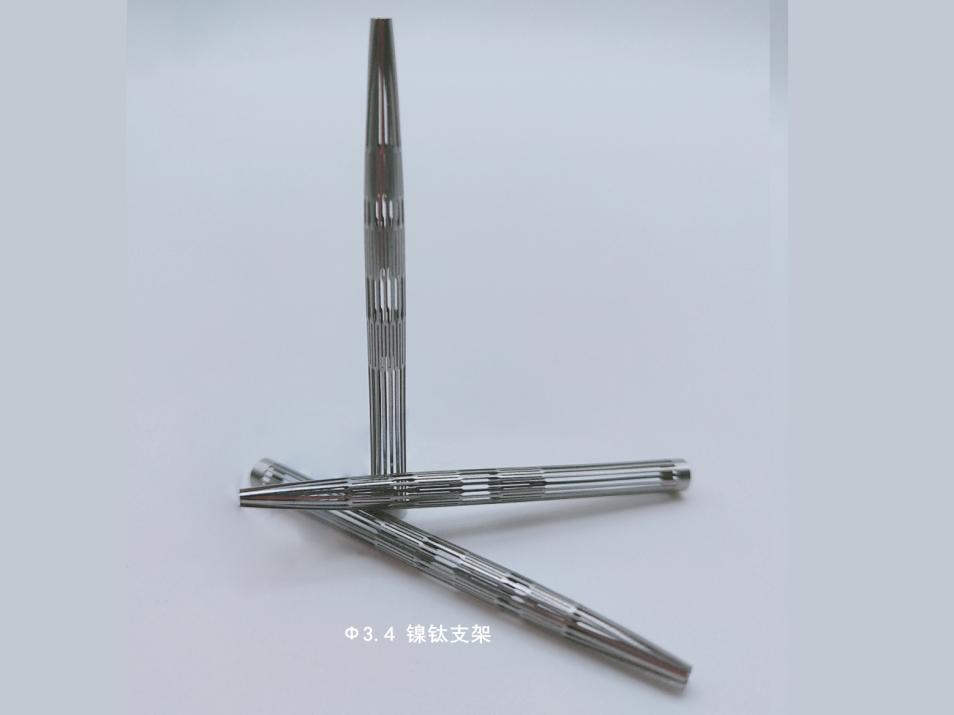

Ni-Ti-Φ 2.7mm-

WT0.2 hli coronary stent

L605-Φ1.8mm-WT0.15 hli

tshuaj coated coronary stent

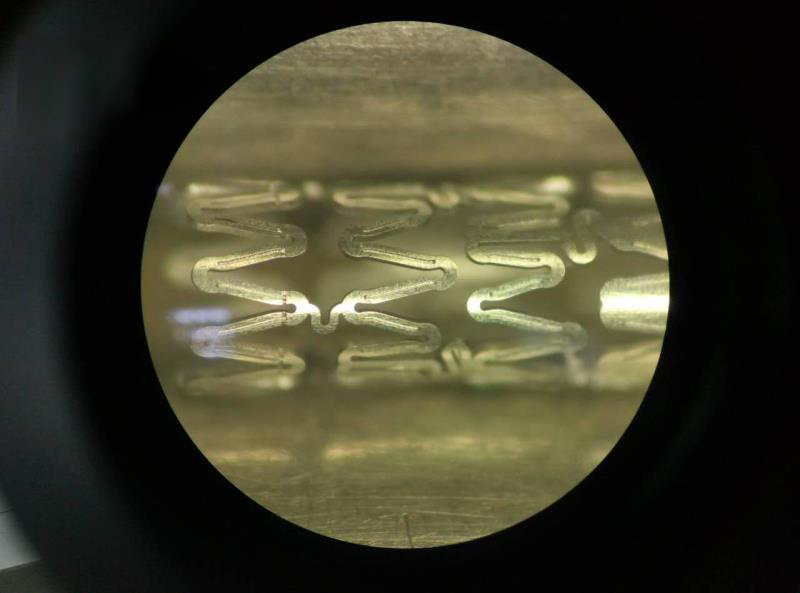

microstructure

Ni-Ti-Φ 2mm-L100mm

-WT0.2 hli coronarystent

Ni-Ti-Φ 3.4mm-WT0.2mm

coronary stent

Φ2.03mm-WT0.2mm

venous lim microstructure

Daim ntawv thovstiv

Laser micromachining ntawm liab qab hlau stent thiab tshuaj coated stent xws li coronary artery stent thiab leeg lim

High precision machining

Me txiav seam dav: <20um

High machining raug: ≤ ± 5um

Qhov zoo ntawm kev txiav: tsis muaj burr & du incision

High machining efficiency: ib-tawm txiav los ntawm ib sab yeeb nkab phab ntsa & nruam tsis siv neeg pub machinin

Sqhov adaptability

Muaj peev xwm ntawm laser qhuav txiav & ntub txiav & drilling & dig muag slotting thiab lwm yam zoo machining tshuab

Txhawb lub centripetal, ntsug thiab compound qhib feature machining ntawm vaj huam sib luag txoj kab uas hla, sib txawv txoj kab uas hla raj thiab dav hlau ntsuas

316L & Ni-Ti & L605 & Fe & Mg & Zn thiab lwm yam ntaub ntawv alloy

Compatible nrog precision D-hom chuck & ER series chuck & peb lub puab tsaig chuck thiab lwm yam precision nyias-walled raj clamping system

Txais yuav ua ke nrog precision nyias-walled tube ncej tes tsho txhawb nqa system nrog tus kheej-adaptive duab kam rau ua variation

Muab cov tswv yim sib txuam ntawm precision nyias-walled raj nruam tsis siv neeg pub machining & qhuav / ntub txiav thiab sealing khoom tau txais

Nruab nrog tus kheej tsim 2D & 2.5D & 3D CAM software system rau laser micromachinin

Yooj yim tsim

Ua raws li lub tswv yim tsim ntawm ergonomics, ilv thiab concise

Nrog lub tshuab tsis pom kev rau lub sijhawm hauv online saib xyuas cov txheej txheem laser dynamic machining

Cov software thiab kho vajtse ua haujlwm sib phim yooj yim, txhawb nqa tus kheej muaj nuj nqi configuration & ntse tswj ntau lawm

Txhawb kev tsim kho tshiab los ntawm qib theem mus rau qib system

Qhib hom tswj & laser micromachining software system yog yooj yim rau kev khiav lag luam & intuitive interface

Daim ntawv pov thawj technical

CE daim ntawv pov thawj

Daim ntawv pov thawj ISO 9001 tau lees paub

Daim ntawv pov thawj ISO 13485

Ua lub luag haujlwm tag nrho kom txaus siab rau txhua qhov kev xav tau ntawm peb cov neeg yuav khoom;tau txais kev nce qib txuas ntxiv los ntawm kev txhawb nqa kev nce qib ntawm peb cov neeg siv khoom;loj hlob los ua qhov kawg kev koom tes ruaj khov ntawm cov neeg siv khoom thiab ua kom muaj kev txaus siab ntawm cov neeg yuav khoom rau Kev Tsim Nrov Zoo rau OEM Bending Sheet Hlau Laser Txiav Part Hoobkas Nqe, Ib txwm rau feem coob ntawm cov neeg siv khoom lag luam thiab cov neeg lag luam muab cov khoom zoo tshaj plaws thiab cov kev pabcuam zoo tshaj plaws.Zoo siab txais tos tuaj koom nrog peb, cia kev tsim kho tshiab ua ke, ua npau suav ya.

Nrov Tsim rauTuam Tshoj Hlau Casting Part thiab Hlau Txiav Part, Peb tenet yog "kev ncaj ncees ua ntej, zoo tshaj plaws".Tam sim no peb muaj kev ntseeg siab los muab kev pabcuam zoo thiab cov khoom zoo rau koj.Peb cia siab tias peb tuaj yeem tsim kom muaj kev sib koom tes ua lag luam nrog koj yav tom ntej!

Cov xov xwm ntsig txog

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur