Precision laser

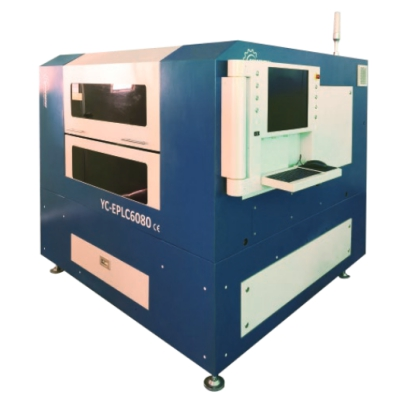

EPLC6080 Precision Optical Fiber Laser Tej Tshuab rau PCB substrate

PCB Substrate Precision Fiber Laser Tej Tshuab

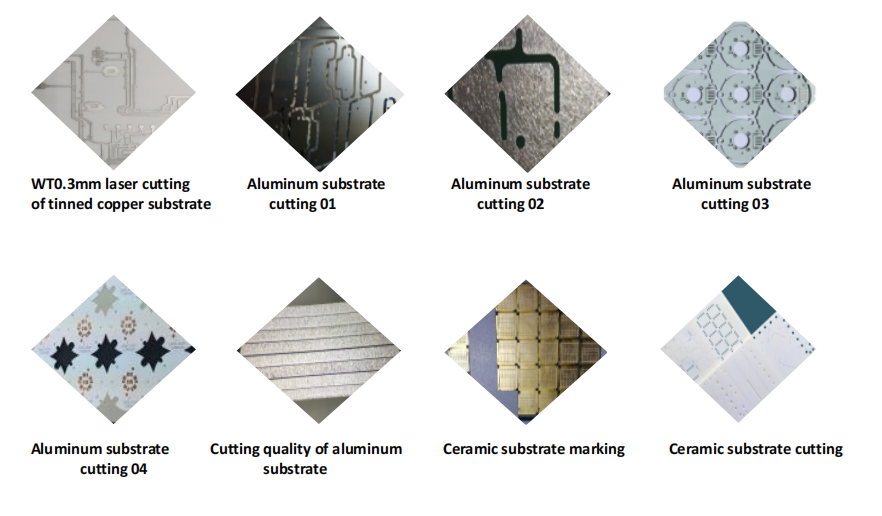

PCB substrate precision fiber ntau laser txiav tshuab yog tsuas yog siv rau laser microprocessing xws li laser txiav, drilling thiab scribing ntawm ntau yam PCB substrates, uas tuaj yeem raug xa mus rau PCB laser txiav tshuab luv luv.Xws li PCB aluminium substrate txiav thiab sib sau, tooj liab substrate txiav thiab sib sau, ceramic substrate txiav thiab sib sau, tinned tooj liab substrate laser sib sau, nti txiav thiab sib sau, thiab lwm yam.

Technical Parameters:

| Kev khiav hauj lwm ceev tshaj plaws | 1000mm / s (X) ; 1000mm / s (Yl & Y2) 50mm / s (Z) |

| Positioning raug | ± 3um (X) ± 3um (Y1 & Y2) ; ± 5um (Z) ; |

| Repetical positioning raug | ± lum (X) ± lum (Y1 & Y2) ± 3um (Z) ; |

| Machining khoom | precision stainless hlau, nyuaj alloy steel thiab lwm yam ntaub ntawv ua ntej los yog tom qab kho deg |

| Khoom phab ntsa thickness | 0 ~ 2.0 ± 0.02 hli; |

| Plane machining ntau yam | 600mm * 800mm; |

| Laser hom | Fiber ntau laser; |

| Laser wavelength | 1030-1070 ± 10nm; |

| laser zog | CW1000W&CW2000W&QCW150W&QCW450W&QCW750W rau kev xaiv; |

| Cov khoom siv hluav taws xob | 220V ± 10%, 50Hz; AC 30A (lub ntsiab Circuit Court breaker); |

| Cov ntaub ntawv hom | DXF, DWG; |

| Cov khoom siv qhov ntev | 1750mm * 1850mm * 1600mm; |

| Khoom hnyav | 1800Kg; |

Qauv Exhibition:

Daim ntawv thov Scope

Laser micromachining ntawm dav hlau thiab nkhaus nto seev ntawm precision stainless hlau thiab nyuaj alloy ua ntej los yog tom qab kev kho mob nto

High precision machining

Me txiav seam dav: 20 ~ 40um

High machining raug: ≤ ± 10um

Zoo zoo ntawm kev txiav: du incision & me me tshav kub cuam tshuam cheeb tsam & tsawg burr

Kev kho qhov loj me: yam khoom tsawg kawg yog 100um

Muaj zog adaptability

Muaj peev xwm ntawm laser txiav, drilling, cim thiab lwm yam zoo machining ntawm PCB substrate

Lub tshuab tuaj yeem siv PCB aluminium substrate, tooj liab substrate, ceramic substrate thiab lwm yam ntaub ntawv

Nruab nrog tus kheej-tsim direct-tsav mobile dual-tsav precision suab platform, granite platform & kaw shafting configuration

Muab ob txoj haujlwm & pom kev pom & tsis siv neeg thauj khoom thiab tshem tawm qhov system & lwm yam kev xaiv ua haujlwm

օ Nruab nrog tus kheej tsim ntev & luv focal ntev ntse nozzle & tiaj tus nozzle laser txiav lub taub hau օ Nruab nrog customized nqus adsorption clamping fixture & slag plua plav sib cais module & plua plav tshem tawm cov kav dej & kev nyab xeeb tawg-pov thawj kev kho mob

Nruab nrog tus kheej tsim 2D & 2.5D & CAM software system rau laser micromachining

Yooj yim tsim

Ua raws li lub tswv yim tsim ntawm ergonomics, ilv thiab concise

Cov software yooj yim & kho vajtse muaj nuj nqi collocation, txhawb tus kheej muaj nuj nqi configuration & ntse ntau lawm tswj

Txhawb kev tsim kho tshiab zoo los ntawm qib theem mus rau qib system

Qhib tswj & laser micromachining software system yooj yim rau kev khiav lag luam & intuitive interface

Daim ntawv pov thawj technical

CE daim ntawv pov thawj

Daim ntawv pov thawj ISO 9001 tau lees paub

IATF 16949 Kev Tswj Xyuas Kev Tswj Xyuas Kev Lag Luam

Cov xov xwm ntsig txog

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur