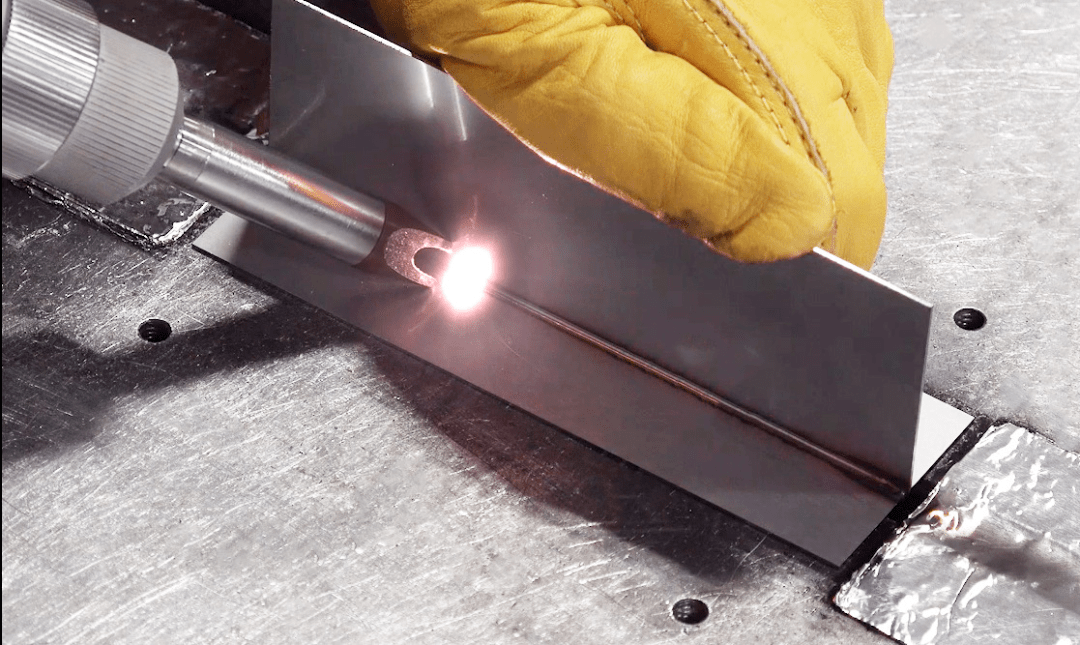

Raws li txhua tus neeg hauv lub voj voog vuam paub, tsoos MIG vuam thiab TIG vuam yog dav siv hauv kev lag luam.Txawm li cas los xij, ob txoj kev vuam no muaj kev xav tau siab rau kev txawj ntse ntawm cov welders.Welders yuav tsum tau siv sijhawm ntau los ua kom paub qhov tseem ceeb ntawm vuam.Lub laser handheld vuam system ua rau nws yooj yim heev rau cov neeg zoo tib yam pib, thiab tuaj yeem tau txais cov txiaj ntsig zoo vuam zoo.

Peb tau ua ntau yam kev ntsuam xyuas kev ua tau zoo ntawm cov qauv vuam ntawm cov khoom siv laser vuam, xws li nro, khoov, thiab metallography.Tom ntej no, cia peb saib seb qhov vuam zoo ntawm lub tes tuav laser vuam system puas tuaj yeem dhau qhov kev xeem tiav.

01, Nta

• Lub zog laser muaj txog li 1500W.Rau cov ntaub ntawv sib txawv thiab cov thicknesses, qhov zoo tshaj plaws vuam chaw tuaj yeem xaiv tau sai los ntawm kev hloov kho qhov xav tau.

• Siv 74 khaws cia preset thiab tus neeg siv-txhais cov txheej txheem tsis pub dhau los ua kom cov neeg siv vuam tshiab tuaj yeem ua haujlwm vuam los ntawm ob peb teev ntawm kev cob qhia.

• Xaiv hom cia kom muab lub zog siab tshaj plaws txog li 2500W, kom muaj peev xwm vuam zoo dua.

• Ib qho kev tu tshiab yog ntxiv rau ntawm lub hauv paus qub, uas tuaj yeem tshem tau cov roj, xeb, thiab txheej tau sai thiab yooj yim ua ntej vuam, thiab tshem tawm cov seem seem thiab oxidation discoloration tom qab vuam.Cov weld zoo nkauj tuaj yeem tau txais yam tsis muaj kev siv tshuaj abrasives lossis tshuaj, txuag nqi ntxiv thiab sijhawm.

02, Weldable cov ntaub ntawv

| Material Science | ThicknessIb sab weld | ThicknessOb sab weld |

| stainless hlau | 4mm ib | 10 hli |

| hlau me me | 4mm ib | 10 hli |

| aluminium | 4mm ib | 10 hli |

| tooj liab | 1 hli | 2 hli |

03, Qhov zoo

• High welding: 4 lub sij hawm sai dua li ib txwm vuam, ua kom cov khoom tsim tau thiab txo tus nqi ntawm txhua qhov haujlwm.

• High vuam zoo: Uniformly welded cov ntaub ntawv tuab, cov ntaub ntawv nyias, thiab cov hlau reflective yam tsis muaj deformation, undercut, los yog hlawv-los ntawm, thiab tshav kub-kho cheeb tsam yog heev me me.

• Yooj yim rau siv: Kev teeb tsa yooj yim, kev kawm, thiab kev ua haujlwm nrog kev nyuaj siab, tuaj yeem paub qhov zoo ntawm vuam thiab tu.

• Weld tsos: Roj stain, xeb, thiab txheej yuav tsum tau muab tshem tawm ua ntej welding, thiab deg residue thiab oxidation discoloration yuav tsum tau muab tshem tawm tom qab vuam, txuag lub sij hawm thiab nqi ntawm kev siv abrasives los yog tshuaj.

• Ntau yam ntawm cov ntaub ntawv: Hlau sib txawv thicknesses, ultra-nyias qhov chaw, tooj liab vuam, thiab cov ntaub ntawv uas sib txawv conductivity.

• Lub viav vias vuam: Lub viav vias dav yog li 5 hli, txhim kho qhov vuam muaj peev xwm thiab qhov siab qhov vuam zoo nkauj.

• Kev nyab xeeb ntawm tus neeg teb xov tooj: Multistage sensors thiab interlocking kev nyab xeeb khoom siv

| Cov txheej txheem vuam tsoos | Laser vuam | |

| vuam ceev | zoo tib yam | Ntau tshaj 4 npaug sai dua |

| vuam zoo | Nyob ntawm tus neeg siv kev paub dhau los | Cov nyhuv zoo |

| Kawm nyuaj | nyuaj | Yooj yim rau siv |

| Kev npaj rau workpiece vuam | Kev npaj yog qhov tseem ceeb thiab teeb meem | Kev npaj tsawg dua thiab yooj yim |

| Workpiece npaj ua ntej welding Cov ntaub ntawv yooj | Txwv los ntawm kev hloov khoom siv | Dav dav, tsis tas yuav teeb tsa |

| Thaum tshav kub kub cuam tshuam cheeb tsam | loj | Me me |

| Khoov thiab deformation | Yooj yim heev rau deform | Tsis yooj yim rau deform |

| Vuam welding | Tsis muaj | Swing dav mus txog 5mm |

04. Technical parameters

| laser zog | Siab siab zog | zog | Hom cia muaj peev xwm | Ntxuav davthiab ntev | Viav ntevthiab zaus | Qhov ntev(L * W * H) | hnyav |

| 1500 W | 2500 W | 220V,24 A | 74 | 15 hli | Txog li 300H,mus 5mm | 641 * 316 * 534 hli | 53Kg ua |

Peb tuaj yeem pom tias qhov kev ua tau zoo ntawm laser tes tuav vuam yog qhov zoo tshaj rau TIG vuam tsoos thiab MIG vuam hauv ntau yam.Tej zaum tsis ntev, qhov chaw vuam yuav yog lub ntiaj teb ntawm laser tes tuav vuam.

Lub sij hawm xa tuaj: Nov-30-2022