Fixture System rau Laser Brazing

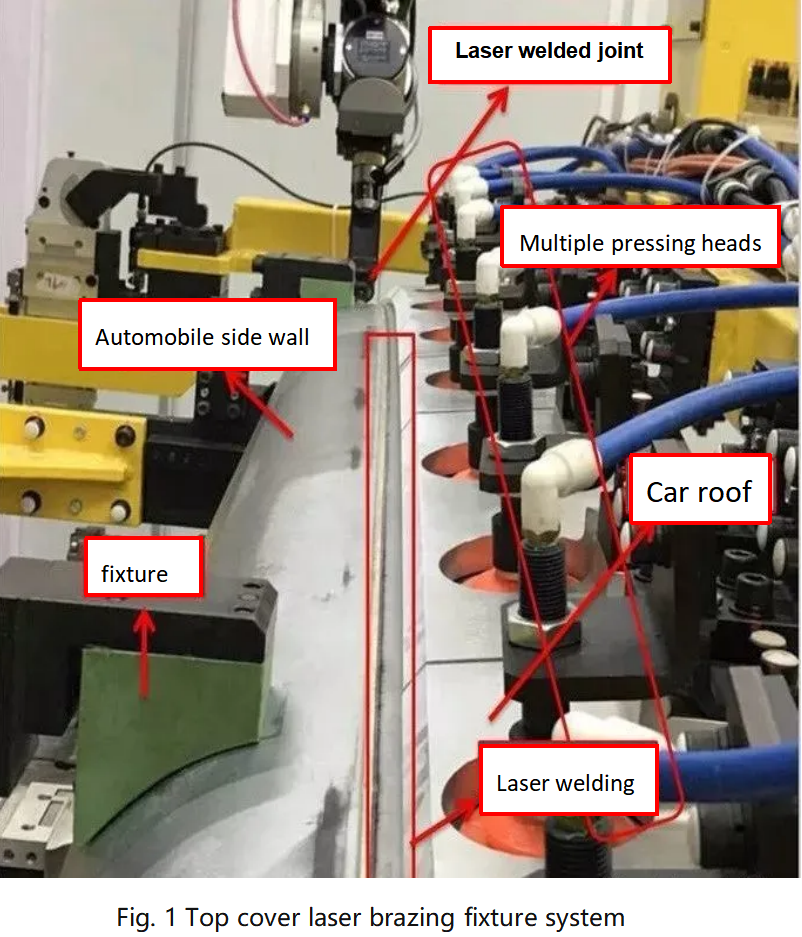

Thaum lub sij hawm laser welding, nws yog ib qho tsim nyog yuav tsum tau clamp lub welded steel phaj ruaj txaus, yog li tshwj xeeb clamps yuav tsim.Lub laser vuam fixture muaj ib tug loj ntim thiab complex qauv.Nws yog ib tug ncej tag nrho.Sab laug thiab sab xis ntawm lub tsheb lub cev tau txais kev txhawb nqa los ntawm cov khoom thaiv thiab clamped los ntawm lub tog raj kheej tom qab tso thiab kev txhawb nqa.Lub sab sauv yog tsim nrog ib tug tshwj xeeb positioning thiab nias gripper rau laser brazing ntawm lub tsheb ru tsev, uas yog nias nrog ntau lub taub hau.Cov neeg hlau rub lub ru tsev, muab tso rau ntawm lub cev, thiab tuav nws nrog lub tog raj kheej, kom cov npoo ntawm lub cev steel phaj yuav tsum tau welded haum nruj txaus.Raws li pom hauv daim duab 1.

Cov txheej txheem txheej txheem

• · Kub

• · Lub kaum sab xis ntawm qhov teeb meem ntawm lub teeb laser

• · Aggregation thiab defocus

• · Qhov tob tob ntawm vuam

• · Cov nyhuv ntawm vuam ceev ntawm laser vuam zog

Kuaj

• 、 Kev tshuaj xyuas qhov muag

• · Raws li tus qauv German PV 6917 (tuaj yeem tau txais los ntawm kev hu rau tus sau);

• · Kev tshuaj xyuas qhov muag yuav tsum tau ua rau txhua lub rooj sib txoos off-line;

• · Tsom ntsoov rau kev tshawb pom ntawm weld nkag mus (xws li kev nkag tsis tiav, dhau kev nkag mus thiab kub hnyiab los ntawm), thiab coj mus rau hauv tus account qhov xwm txheej ntawm weld (xws li spatter thiab porosity);

Txoj kev ntsuam xyuas ntawm laser brazing pom kev soj ntsuam yog pom nyob rau hauv Table 1.

| Table 1 Kev Ntsuas Kev Ntsuas Zoo ntawm Laser Brazing | ||

| Serial No | Kev piav qhia tsis raug | Kev ntsuam xyuas tsis raug |

| 1 | Tawm pores | Yog tias muaj kev tso cai, qhov chaw tuaj yeem kho tau ntev npaum li nws tsis cuam tshuam rau kev ua haujlwm;Cua qhov nrog txoj kab uas hla ntau dua 0.2 hli yuav tsum tau kho |

| 2 | Solder overflow (ntau dhau) | Yog tias muaj kev tso cai, qhov chaw tuaj yeem kho tau ntev npaum li nws tsis cuam tshuam rau kev ua haujlwm;Yuav kho tau |

| 3 | Txheej ripple ntawm weld nto | Qhov sib koom ua ke yuav tsum tau ntim nrog solder tsis tu ncua;Yuav kho tau |

| 4 | Nto tawg (transverse thiab longitudinal) tshwm sim ntawm weld | Yog tias muaj kev tso cai, qhov chaw tuaj yeem kho tau ntev npaum li nws tsis cuam tshuam rau kev ua haujlwm;Yuav kho tau |

| 5 | Nto tawg (transverse thiab longitudinal) tshwm sim ntawm lub hauv paus hlau | Tsis tsim nyog, yuav tsum tau kho |

| 6 | Base hlau nkag | Tsis tsim nyog, yuav tsum tau kho |

| 7 | Undercut thiab tsis tiav nkag | Tsis tsim nyog, yuav tsum tau kho |

| 8 | spatter | Yog tias muaj kev tso cai, qhov chaw tuaj yeem kho tau ntev npaum li nws tsis cuam tshuam rau kev ua haujlwm;Yuav kho tau |

| 9 | Meatless | Tsis tso cai, yuav tsum tau kho |

| 10 | Qhov pib kawg tsis yog welded, thiab lub davhlau ya nyob twg yog pitted | Tsis tso cai, yuav tsum tau kho |

| 11 | Weld ploj lawm (loj sib piv) | Tsis tso cai, yuav tsum tau kho |

2 、 Kev tshuaj xyuas kev puas tsuaj

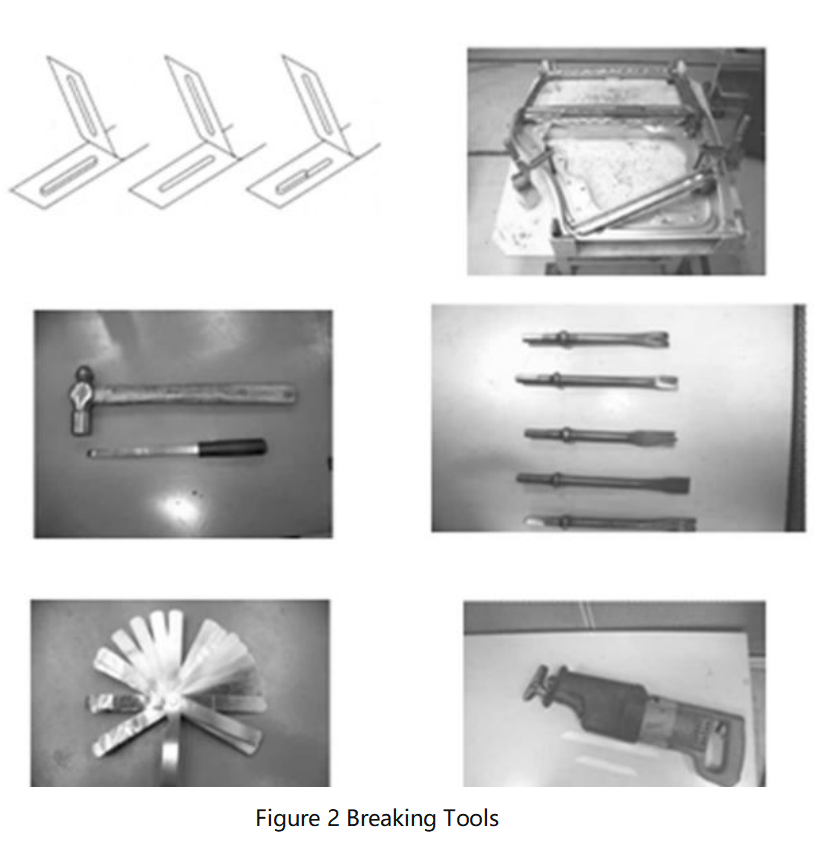

Cov cuab yeej tshuaj xyuas kev puas tsuaj tau pom hauv daim duab 2:

3 、 Metallographic Microscopic Analysis

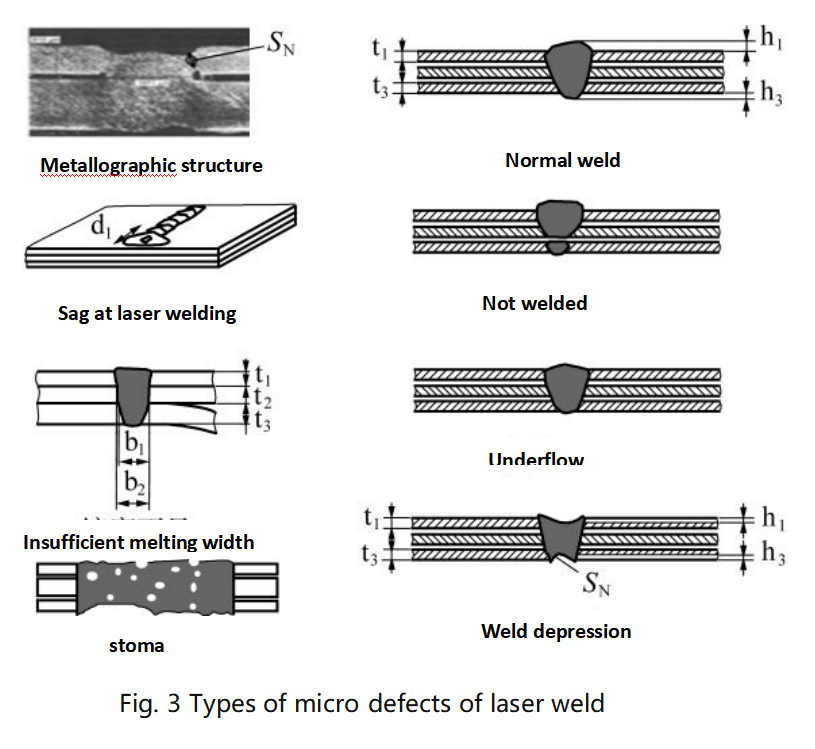

Hom micro defects ntawm laser vuam yog qhia hauv daim duab 3:

4, NDT

Ultrasonic, X-ray thiab lwm yam twj paj nruag tuaj yeem siv los kuaj xyuas lub laser vuam zoo.

Cov ntsiab lus

Raws li qhov tseeb daim ntawv thov ntawm laser vuam tshuab nyob rau hauv lub tsheb cov nroj tsuag, nws yuav pom tau hais tias laser welding tsis tsuas yog txo qhov hnyav ntawm lub tsheb lub cev, txhim kho kev sib dhos raug ntawm lub tsheb lub cev, tab sis kuj zoo heev txhim khu lub zog ntawm lub tsheb. lub cev, muab cov neeg siv nrog kev ruaj ntseg zoo dua thaum txaus siab rau kev nplij siab.Nws ntseeg tau hais tias nrog kev ua haujlwm tsis tu ncua ntawm cov teeb meem laser vuam tshuab thiab kev txhim kho txuas ntxiv ntawm cov txheej txheem tsim, laser vuam yuav dhau los ua ib feem tseem ceeb ntawm lub tsheb yav tom ntej hauv kev tsim khoom dawb.

Post lub sij hawm: Jan-09-2023