Laser nto kev kho mob yog ib tug tshuab uas siv high-power density laser beam kom sov cov ntaub ntawv nto nyob rau hauv ib tug tsis sib cuag txoj kev, thiab paub nws cov kev hloov kho deg los ntawm cov conductive txias ntawm cov khoom nto nws tus kheej.Nws yog qhov zoo los txhim kho cov khoom siv kho tshuab thiab lub cev ntawm cov khoom siv nto, nrog rau kev hnav tsis kam, corrosion kuj thiab qaug zog ntawm qhov chaw.Nyob rau hauv xyoo tas los no, laser nto kho technologies xws li laser tu, laser quenching, laser alloying, laser poob siab zog thiab laser annealing, nrog rau laser cladding, laser 3D printing, laser electroplating thiab lwm yam laser additive manufacturing technologies tau ushered nyob rau hauv dav daim ntawv thov prospects. .

1. Laser ntxuav

Laser tu yog ib qho kev txhim kho sai sai ntawm qhov chaw tu tshuab, uas siv lub zog pulse laser beam rau irradiate nto ntawm lub workpiece, kom cov av, hais los yog txheej nyob rau saum npoo yuav evaporate los yog nthuav tam sim ntawd, yog li ua tiav cov txheej txheem ntawm tu. thiab purification.Laser tu feem ntau muab faib ua xeb tshem tawm, tshem tawm roj, tshem tawm xim, txheej tshem tawm thiab lwm yam txheej txheem;Nws yog tsuas yog siv rau cov hlau tu, kab lis kev cai relics tu, architecture tu, thiab lwm yam Raws li nws cov kev ua haujlwm, kev ua haujlwm raug thiab hloov tau yooj yim, kev ua haujlwm siab thiab kev txuag hluav taws xob, kev tiv thaiv ib puag ncig ntsuab, tsis muaj kev puas tsuaj rau lub substrate, kev txawj ntse, kev tu zoo, kev nyab xeeb, daim ntawv thov dav thiab lwm yam ntxwv thiab qhov zoo, nws tau dhau los ua neeg nyiam hauv ntau yam kev lag luam.

Piv nrog rau cov kev tu ib txwm siv xws li kev sib txhuam kev sib txhuam, tshuaj txhuam hniav tu, cov khoom ua kua muaj zog ua haujlwm tu, kev tu ultrasonic siab, laser tu muaj qhov zoo.

2. Laser quenching

Laser quenching siv high-zog laser raws li lub tshav kub qhov chaw ua rau cov hlau nto kub thiab txias sai sai.Cov txheej txheem quenching yog ua tiav tam sim ntawd kom tau txais qhov siab hardness thiab ultra-fine martensite qauv, txhim kho hardness thiab hnav tsis kam ntawm cov hlau nto, thiab tsim compressive kev nyuaj siab rau saum npoo los txhim kho qhov qaug zog.Cov txiaj ntsig tseem ceeb ntawm cov txheej txheem no suav nrog thaj chaw me me thaum tshav kub kub cuam tshuam, me me deformation, qib siab ntawm automation, kev yooj yim ntawm kev xaiv quenching, siab hardness ntawm refined nplej, thiab ntse ib puag ncig tiv thaiv.Piv txwv li, qhov chaw laser tuaj yeem hloov kho kom quench txhua txoj haujlwm dav;Qhov thib ob, lub taub hau laser thiab ntau axis neeg hlau txuas tuaj yeem tua qhov chaw xaiv ntawm qhov nyuaj.Piv txwv li, laser quenching yog kub heev thiab ceev, thiab quenching kev nyuaj siab thiab deformation yog me me.Lub deformation ntawm lub workpiece ua ntej thiab tom qab laser quenching yuav luag tsis quav ntsej, yog li nws yog tshwj xeeb tshaj yog haum rau kev kho deg ntawm qhov chaw nrog high precision yuav tsum.

Tam sim no, laser quenching tau ua tiav rau qhov kev txhim kho ntawm qhov chaw tsis muaj zog hauv kev lag luam tsheb, kev lag luam pwm, cov cuab yeej kho vajtse thiab tshuab kev lag luam, tshwj xeeb tshaj yog nyob rau hauv kev txhim kho cov kev pab cuam lub neej ntawm cov khoom tsis zoo xws li lub zog, ncej nto, kev taw qhia, lub puab tsaig thiab pwm.Cov yam ntxwv ntawm laser quenching yog raws li nram no:

(1) Laser quenching yog lub cua sov ceev thiab nws tus kheej zoo siab txias txheej txheem, uas tsis tas yuav tsum tau lub cub tawg kub preservation thiab coolant quenching.Nws yog cov txheej txheem tsis muaj kuab paug, ntsuab thiab ib puag ncig-phooj ywg kev kho cua sov, thiab tuaj yeem siv tau yooj yim quenching rau saum npoo ntawm pwm loj;

(2) Raws li lub laser cua sov ceev ceev, lub tshav kub cuam tshuam cheeb tsam yog me me, thiab nto scanning cua sov quenching, uas yog, instantaneous lub zos cua sov quenching, lub deformation ntawm kho tuag yog heev me me;

(3) Vim lub me me divergence lub kaum sab xis ntawm lub laser beam, nws muaj zoo directivity, thiab muaj peev xwm kom meej lub zos quench lub pwm nto los ntawm lub teeb qhia system;

(4) Lub hardened txheej tob ntawm laser nto quenching yog feem ntau 0.3-1.5 hli.

3. Laser annealing

Laser annealing yog txheej txheem kev kho cua sov uas siv laser los ua kom sov cov khoom nto, nthuav tawm cov khoom mus rau qhov kub thiab txias rau lub sijhawm ntev, thiab tom qab ntawd maj mam txias.Lub hom phiaj tseem ceeb ntawm cov txheej txheem no yog tso tawm kev ntxhov siab, ua kom cov khoom ductility thiab toughness, thiab tsim tshwj xeeb microstructure.Nws yog tus cwj pwm los ntawm lub peev xwm los kho cov qauv matrix, txo hardness, refine nplej thiab tshem tawm cov kev ntxhov siab sab hauv.Nyob rau hauv xyoo tas los no, laser annealing thev naus laus zis kuj tau dhau los ua cov txheej txheem tshiab hauv kev lag luam semiconductor, uas tuaj yeem txhim kho kev sib koom ua ke ntawm kev sib koom ua ke.

4. Laser poob siab zog

Laser poob siab zog thev naus laus zis yog ib qho tshiab thiab cov thev naus laus zis siab uas siv cov plasma shock yoj tsim los ntawm lub teeb laser muaj zog los txhim kho kev tiv thaiv qaug zog, hnav tsis kam thiab corrosion kuj ntawm cov ntaub ntawv hlau.Nws muaj ntau yam zoo, xws li tsis muaj tshav kub cuam tshuam cheeb tsam, siab zog efficiency, ultra-siab strain tus nqi, muaj zog controllability thiab zoo kawg li ntxiv dag zog rau cov nyhuv.Nyob rau tib lub sijhawm, laser poob siab ntxiv dag zog muaj cov yam ntxwv ntawm kev sib sib zog nqus cov kev ntxhov siab, zoo microstructure thiab kev ncaj ncees saum npoo, zoo thermal stability thiab lub neej ntev.Nyob rau hauv xyoo tas los no, cov thev naus laus zis no tau ua tiav kev txhim kho sai, thiab muaj lub luag haujlwm zoo hauv aerospace, kev tiv thaiv hauv tebchaws thiab kev lag luam tub rog thiab lwm yam haujlwm.Tsis tas li ntawd, cov txheej yog tsuas yog siv los tiv thaiv lub workpiece los ntawm laser hlawv thiab txhim khu kev nqus ntawm laser zog.Tam sim no, cov khoom siv feem ntau siv yog xim dub thiab txhuas ntawv ci.

Laser peening (LP), tseem hu ua laser shock peening (LSP), yog ib txoj kev siv nyob rau hauv lub tshav pob engineering, uas yog, siv cov mem tes high-power laser beams los tsim cov residual stresses nyob rau hauv cov ntaub ntawv los txhim kho cov hnav tsis kam. (xws li hnav tsis kam thiab qaug zog ua haujlwm) ntawm cov khoom siv, los yog txhim kho lub zog ntawm cov ntu nyias ntawm cov ntaub ntawv los txhim kho qhov tawv tawv ntawm cov ntaub ntawv.

Tsis zoo li feem ntau cov ntaub ntawv ua cov ntaub ntawv, LSP tsis siv lub zog laser rau kev kho cua sov kom ua tiav cov txiaj ntsig xav tau, tab sis siv cov nqaj cuam tshuam rau kev ua tshuab.Lub zog loj laser beam yog siv los cuam tshuam rau saum npoo ntawm lub hom phiaj workpiece nrog lub zog siab luv luv mem tes.

Lub teeb beam cuam tshuam cov hlau workpiece, vaporizes lub workpiece mus rau hauv ib tug nyias plasma xeev tam sim ntawd, thiab siv shocks yoj siab rau lub workpiece.Qee lub sij hawm ib txheej nyias ntawm cov khoom siv opaque cladding ntxiv rau lub workpiece los hloov cov hlau evaporation.Txhawm rau kom siab, lwm cov ntaub ntawv pob tshab los yog cov txheej txheem cuam tshuam tsis zoo yog siv los ntes cov ntshav (feem ntau yog dej).

Plasma ua rau muaj kev cuam tshuam yoj, rov ua dua qhov microstructure ntawm qhov chaw ua haujlwm ntawm qhov cuam tshuam, thiab tom qab ntawd tsim cov tshuaj tiv thaiv ntawm cov hlau nthuav dav thiab compression.Qhov sib sib zog nqus compressive kev ntxhov siab tsim los ntawm cov tshuaj tiv thaiv no tuaj yeem txuas lub neej ntawm cov khoom.

5. Laser alloying

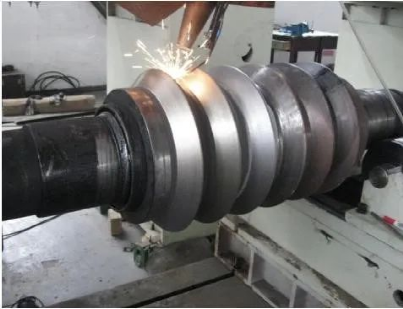

Laser alloying yog ib qho kev hloov kho saum npoo av tshiab, uas tuaj yeem siv los npaj amorphous nanocrystalline reinforced cermet composite coatings rau ntawm qhov chaw ntawm cov txheej txheem raws li cov kev pabcuam sib txawv ntawm cov ntaub ntawv aviation thiab cov yam ntxwv ntawm lub zog siab ceev laser beam cua sov thiab condensation tus nqi, yog li raws li kev ua tiav lub hom phiaj ntawm kev hloov kho saum npoo ntawm cov khoom siv dav hlau.Piv nrog laser alloying tshuab, laser cladding tshuab muaj cov yam ntxwv ntawm me me dilution piv ntawm substrate rau molten pas dej ua ke, me me tshav kub cuam tshuam cheeb tsam, me me thermal deformation ntawm workpiece thiab me me seem ntawm workpiece tom qab laser cladding kho.Laser cladding tuaj yeem txhim kho cov khoom saum npoo ntawm cov khoom, thiab kho cov khoom hnav.Nws muaj cov yam ntxwv ntawm kev ua haujlwm siab, ceev ceev, ntsuab ib puag ncig tiv thaiv thiab tsis muaj kuab paug, thiab kev ua haujlwm zoo ntawm workpiece tom qab kho.

Laser cladding thev naus laus zis kuj yog ib qho ntawm cov kev hloov kho saum npoo av tshiab uas sawv cev rau txoj kev loj hlob thiab theem ntawm kev tsim kho saum npoo av.Laser cladding thev naus laus zis tau dhau los ua qhov kev tshawb fawb hotspot hauv kev hloov kho saum npoo ntawm titanium alloys vim nws qhov zoo ntawm kev tsis muaj kuab lom thiab kev sib xyaw ua ke ntawm cov txheej txheem thiab cov txheej txheem.Laser cladding ceramic txheej los yog ceramic particle reinforced composite txheej yog ib txoj hauv kev zoo los txhim kho qhov hnav tsis kam ntawm titanium alloy.Raws li kev ua haujlwm tiag tiag, xaiv cov khoom tsim nyog, thiab cov tshuab laser cladding tuaj yeem ua tiav cov txheej txheem zoo tshaj plaws.Laser cladding tshuab tuaj yeem kho ntau yam ua tsis tiav, xws li aeroengine hniav.

Qhov sib txawv ntawm laser nto alloying thiab laser nto cladding yog tias laser nto alloying yog tag nrho sib xyaw cov ntsiab lus alloy ntxiv thiab txheej txheej ntawm cov substrate hauv cov kua hauv lub xeev los tsim cov txheej txheem alloying;Laser nto cladding yog yaj tag nrho cov precoating thiab micro yaj lub substrate nto, thiaj li hais tias cov cladding txheej thiab cov khoom siv substrate tsim ib tug metallurgical ua ke thiab ua kom muaj pes tsawg leeg ntawm cladding txheej yeej tsis hloov.Laser alloying thiab laser cladding tshuab yog tsuas yog siv los txhim kho qhov hnav tsis kam, corrosion kuj thiab grading kuj ntawm titanium alloys.

Tam sim no, laser cladding thev naus laus zis tau siv dav hauv kev kho thiab hloov kho ntawm cov hlau nto.Txawm li cas los xij, txawm hais tias cov tsoos laser cladding muaj qhov zoo thiab cov yam ntxwv ntawm kev hloov pauv tau yooj yim, kho tshwj xeeb zoo li tus neeg siv cov khoom siv ntxiv, thiab lwm yam, nws cov kev ua haujlwm qis qis, thiab nws tseem tsis tuaj yeem ua tau raws li qhov yuav tsum tau ua ntawm kev tsim khoom loj thiab kev ua haujlwm hauv kev lag luam. qee qhov chaw tsim khoom.Txhawm rau ua kom tau raws li qhov xav tau ntawm ntau lawm thiab txhim kho kev ua haujlwm ntawm cladding, high-speed laser cladding technology tau los ua.

Kev kub ceev laser cladding thev naus laus zis tuaj yeem paub txog kev cog lus compact thiab tsis xws luag dawb cladding txheej.Qhov zoo ntawm cov txheej txheej cladding yog compact, metallurgical bonding nrog lub substrate, tsis muaj qhib qhov tsis xws luag, thiab nto yog du.Nws tuaj yeem tsis tsuas yog ua tiav ntawm lub cev hloov pauv, tab sis kuj nyob rau hauv lub dav hlau thiab complex nto.Los ntawm kev ua kom zoo dua qub, cov thev naus laus zis no tuaj yeem siv dav hauv cov thee, metallurgy, offshore platforms, ntawv ua, cov khoom siv pej xeem, tsheb, nkoj, roj av, aerospace industries, thiab dhau los ua cov txheej txheem ntsuab remanufacturing uas tuaj yeem hloov cov tsoos electroplating technology.

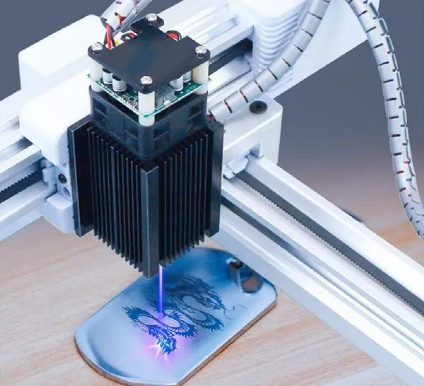

7. Laser engraving

Laser engraving yog txheej txheem laser uas siv CNC thev naus laus zis los ua haujlwm siab-zog laser beam rau ntawm cov khoom nto, thiab siv cov nyhuv thermal generated los ntawm laser los tsim cov qauv ntshiab ntawm cov khoom nto.Lub cev denaturation ntawm melting thiab gasification ntawm kev ua cov ntaub ntawv nyob rau hauv lub irradiation ntawm laser engraving yuav pab tau laser engraving kom ua tiav cov hom phiaj.Laser engraving yog siv laser los kos cov lus ntawm ib yam khoom.Cov lus carved los ntawm cov cuab yeej no tsis muaj nicks, qhov saum npoo ntawm cov khoom yog du thiab tiaj tus, thiab cov ntawv sau yuav tsis hnav.Nws cov yam ntxwv thiab qhov zoo muaj xws li: nyab xeeb thiab txhim khu kev qha;Precise thiab ceev faj, qhov precision tuaj yeem ncav cuag 0.02mm;Txuag kev tiv thaiv ib puag ncig thiab cov khoom siv thaum ua tiav;Kev kub ceev, kev kub ceev engraving raws li cov zis kos duab;Tus nqi qis, tsis txwv los ntawm kev ua kom muaj nuj nqis, thiab lwm yam.

8. Laser 3D luam ntawv

Cov txheej txheem siv tshuab laser cladding, uas siv laser irradiate cov hmoov ntws los ntawm lub nozzle mus ncaj qha yaj cov khoom yooj yim los yog alloy hmoov.Tom qab lub laser beam tawm, cov kua alloy solidifies sai sai kom paub qhov ceev prototyping ntawm alloy.Tam sim no, nws tau siv dav hauv kev tsim qauv, tshuab tsim, aerospace, tub rog, architecture, zaj duab xis thiab TV, khoom siv hauv tsev, kev lag luam teeb, tshuaj, archaeology, kab lis kev cai thiab kos duab, duab puab, hniav nyiaj hniav kub thiab lwm yam.

9. Hom kev lag luam ntawm laser nto kho thiab remanufacturing

Tam sim no, laser nto kho thiab additive manufacturing technologies, txheej txheem thiab khoom siv lug siv nyob rau hauv metallurgy, mining machinery, pwm, roj av hwj chim, kho vajtse, rail transit, aerospace, machinery thiab lwm yam lag luam.

10. Daim ntawv thov ntawm laser electroplating tshuab

Laser electroplating yog ib tug tshiab high-zog beam electroplating technology, uas yog ib qho tseem ceeb heev rau kev tsim thiab kho cov microelectronic li thiab loj-scale integrated circuits.Tam sim no, txawm hais tias txoj cai ntawm laser electroplating, laser ablation, plasma laser deposition thiab laser jet tseem nyob rau hauv kev tshawb fawb, lawv cov technologies tau siv.Thaum lub laser nruam los yog mem tes laser irradiates lub cathode nto nyob rau hauv lub electroplating da dej, tsis tsuas yog lub deposition tus nqi ntawm hlau yuav zoo heev, tab sis kuj lub computer yuav siv tau los tswj lub trajectory ntawm lub laser beam kom tau lub unshielded txheej ntawm lub xav kom complex geometry.

Daim ntawv thov ntawm laser electroplating nyob rau hauv kev xyaum yog tsuas yog raws li nram no ob yam ntxwv:

(1) Qhov ceev hauv cheeb tsam laser irradiation yog ntau dua li qhov ceev ntawm electroplating hauv lub cev (txog 103 zaug);

(2) Kev tswj lub peev xwm ntawm laser muaj zog, uas tuaj yeem ua rau qhov tsim nyog ntawm cov khoom precipitate tus nqi ntawm cov hlau.Ordinary electroplating siv qhov chaw ntawm tag nrho cov electrode substrate, thiab cov electroplating ceev yog qeeb, yog li nws yog ib qho nyuaj rau tsim complex thiab zoo qauv.Laser electroplating tuaj yeem kho lub laser beam rau micrometer loj, thiab ua qhov tsis muaj kev tiv thaiv ntawm micrometer loj.Rau kev tsim hluav taws xob, kev kho hluav taws xob thiab kev tso dej hauv zos ntawm microelectronic connector Cheebtsam, hom kev ua haujlwm siab ceev no tau dhau los ua ntau dua.

Piv nrog rau cov electroplating zoo tib yam, nws qhov zoo yog:

(1) Kev ceev ceev ceev, xws li laser kub plating txog 1 μ M / s, laser tooj liab plating txog 10 μ M / s, laser dav hlau kub plating txog 12 μ M / s, laser dav hlau tooj liab plating txog 50 μ m / s;

(2) Hlau deposition tsuas yog tshwm sim nyob rau hauv lub laser irradiation cheeb tsam, thiab lub zos deposition txheej yuav tau tsis muaj shielding ntsuas, yog li simplifying cov txheej txheem ntau lawm;

(3) Cov txheej txheej adhesion tau zoo heev;

(4) Yooj yim kom paub tswj tsis siv neeg;

(5) Txuag cov hlau muaj nuj nqis;

(6) Txuag cov cuab yeej siv peev nyiaj thiab lub sijhawm ua haujlwm.

Thaum lub laser nruam los yog impulse laser irradiates lub cathode nto nyob rau hauv lub electroplating da dej, tsis tsuas yog lub deposition tus nqi ntawm cov hlau yuav zoo heev, tab sis kuj lub computer muaj peev xwm tswj tau lub zog khiav ntawm lub laser beam kom tau lub unshielded txheej nrog rau txoj kev. geometry.Lub tshuab tshiab tam sim no ntawm laser dav hlau txhim kho electroplating ua ke nrog cov tshuab laser txhim kho electroplating nrog cov tshuaj electroplating txau, kom lub laser thiab cov tshuaj plating tuaj yeem ua rau tib lub sijhawm tua mus rau cathode nto, thiab cov huab hwm coj hloov ceev nrawm dua li qhov loj hloov ceev. ntawm micro stirring tshwm sim los ntawm laser irradiation, yog li ua tau ib tug heev deposition ceev.

Kev txhim kho yav tom ntej thiab kev tsim kho tshiab

Nyob rau hauv lub neej yav tom ntej, txoj kev loj hlob kev taw qhia ntawm laser nto kho mob thiab additive manufacturing khoom yuav tsum tau sau tseg raws li nram no:

· Kev ua haujlwm siab - kev ua haujlwm siab, ua tau raws li cov khoom siv nrawm nrawm ntawm kev lag luam niaj hnub;

· Kev ua haujlwm siab - cov cuab yeej muaj ntau lub zog, kev ua haujlwm ruaj khov thiab tsim nyog rau kev ua haujlwm sib txawv;

· Kev txawj ntse siab - qib ntawm kev txawj ntse tau txhim kho tas li, nrog kev cuam tshuam nrog phau ntawv tsawg dua;

· Tus nqi qis - tus nqi khoom siv yog tswj tau, thiab tus nqi ntawm cov khoom siv tau raug txo;

· Customization - tus kheej customization ntawm cov cuab yeej, meej tom qab-muag kev pab cuam,

· Thiab kev sib xyaw ua ke - sib txuas cov tshuab laser nrog cov txheej txheem ua haujlwm ib txwm muaj.

Post lub sij hawm: Sep-17-2022